Guide to Coveralls

Coveralls are a necessity in many businesses to protect employees from contamination from liquids, dusts, particles and other potentially harmful substances. Our guide to coveralls should ensure you are better prepared and understand the different types of coveralls and various environments and situations where they should be utilised.

Employers have a legal responsibility to provide employees with adequate PPE (Personal Protective Equipment) under The Personal Protective Equipment at Work Regulations

Employers have a legal responsibility to provide employees with adequate PPE (Personal Protective Equipment) under The Personal Protective Equipment at Work Regulations

Since the pandemic, updated guidelines have been published in April 2022 to update the original 1992 Work Regulations, to ensure employers and employees have a full understanding of the responsibilities surrounding the provision, training and usage of PPE for everyone who provides a service to a business on a permanent or casual basis.

PPE must be provided free of charge, and steps must be taken to ensure employees understand how to access it. PPE may include but is not limited to coveralls, gloves, gauntlets, face masks, visors, goggles, helmets, safety boots, overshoes and breathing apparatus if your

work requires it.

The regulations stipulate that employers must ensure that suitable PPE is provided to employees who may be exposed to a risk to their health or safety while at work, except where such risk has been adequately controlled by other means which are equally or more effective than PPE.

Not only must employers provide PPE to protect their workforce, they should also provide training in its usage to ensure its being utilised effectively and worn correctly.

Therefore, its important for any business to undertake risk assessments and highlight areas in which PPE should be used.

What are coveralls?

Coveralls are designed to be used to protect the user against contamination from harmful substances. Worn over clothing, they will protect the users skin from a wide range of liquids, chemicals, dusts or fibres in the workplace. Coveralls are not only used to protect the user they can also be used to prevent human contamination within an environment such as laboratories and crime scenes.

Coveralls, also known a haz suits, disposable suits or chemical protection suits, are available in a vast range of styles, sizes and applications so care should be taken to ensure you are purchasing effective coveralls for your needs, as well as providing appropriate training in donning and doffing of coveralls correctly.

We work alongside Lakeland, a global leader in manufacturing protective clothing. With over 40 years experience of improving the quality of health and safety workwear to provide the safest working environments, they are experts in protecting people, products and the environment.

How do I know what coveralls I need?

As with all aspects of Health and Safety, you should carry out risk assessments to ensure every element of your business is assessed for the requirement of any PPE. Any area where your workforce may be exposed to liquids, sprays or air born particles should be recorded, as well as the length of exposure time, and any opportunity to eliminate the risk or protect from it.

You should ensure you understand the risks and dangers of any substances to make sure you obtain coveralls to protect the wearer. Handy guides such as Lakeland Quick Reference Guide or the ChemMax Chemical Search offer a checklist for various substances and the relevant coveralls to use, in different situations.

Which industries need coveralls?

Which industries need coveralls?

There are several industries that may need to utilise coveralls, these may include

· Pharmaceutical

· Construction

· Manufacturing

· Laboratories

· Industrial

· Automotive

· Engineering

· Petro Chemical

· Oil & Gas

· Transport of chemicals

· Utilities companies

· Waste Handling

· And many more

Any business, in any industry, where employees may come into contact with dusts, gases, chemicals, biological agents or hazardous liquids must provide efficient coveralls and safety wear.

Getting the right fit

Although buying one size fits all coverall suit may save your business money, having the incorrect size or style could cause further, potentially fatal problems, so cost cutting really isn’t worth the risk.

Coveralls which are too big could get caught in machinery, too small and they may limit mobility and productivity. Coveralls should be supplied in the correct size for the user to ensure maximum protection and comfort. As well as size many coveralls have additional features such as reinforced knee panels and storm flaps to protect zips.

Remember coveralls are designed to protect users from health and safety risks at work, it reduces the likelihood of injuries and protects your business from prosecution.

The cost of getting it wrong

Providing employees with incorrect or inadequate PPE could cause serious injuries, or even fatalities so you must ensure your business understands its responsibilities to protect staff if a risk has been highlighted. Full guidelines for your legal requirements can be found on the HSE website.

HSE inspectors already include assessment of PPE as part of their routine inspections. Enforcement action can range from verbal or written advice to enforcement notices and, in the most serious cases, prosecution.

Donning and Doffing Coveralls

Donning and Doffing Coveralls

Care should be taken when putting on and taking off coveralls to ensure any hazardous substances are not transferred to the user during this process. This is referred to as donning and doffing. Our expert partners Lakeland, provide a really useful guide to donning and doffing coveralls correctly

Some aspects to consider:

Ensure you have carried out a risk assessment for the substances you are protecting from. Are they toxic, dangerous or harmful? Are they visible?

Ensure you have a clean (decontaminated if applicable) area, with lots of space. Visually check your coveralls to ensure there are no rips or tears prior to donning.

Read the instructions. It may seem simple but this is often overlooked, resulting in errors being made. Coveralls differ but they should all include a safety data sheet within the package so ensure you read this prior to attempting donning the coveralls to ensure you do this correctly. They also show limitations of use and the exposure or breakthrough times

Pair up. Donning and Doffing is recommended in pairs for two reasons. Firstly, some elements of donning and doffing can only be done effectively by another person, such as final zipping and taping cuffs. Secondly a partner can do a final visual check of your whole donned garment before proceeding into a hazardous area.

Don’t underestimate seals between coveralls and over boots, face wear and gloves. Ensure storm flaps are covered over zips

Once you are happy you have donned correctly, have a final visual check to ensure you are suitably covered.

Once finished and prior to doffing consider if you suit may be contaminated. If there is any chance you need to clean or decontaminate before removing the coveralls.

When doffing ensure you remove in a logical order, rolling down externally. Keep your gloves on until the end to ensure your hands do not become contaminated.

Remember, if in doubt, everything should be included in the safety data sheet so please refer to it

What type of coverall do I need for my business?

What type of coverall do I need for my business?

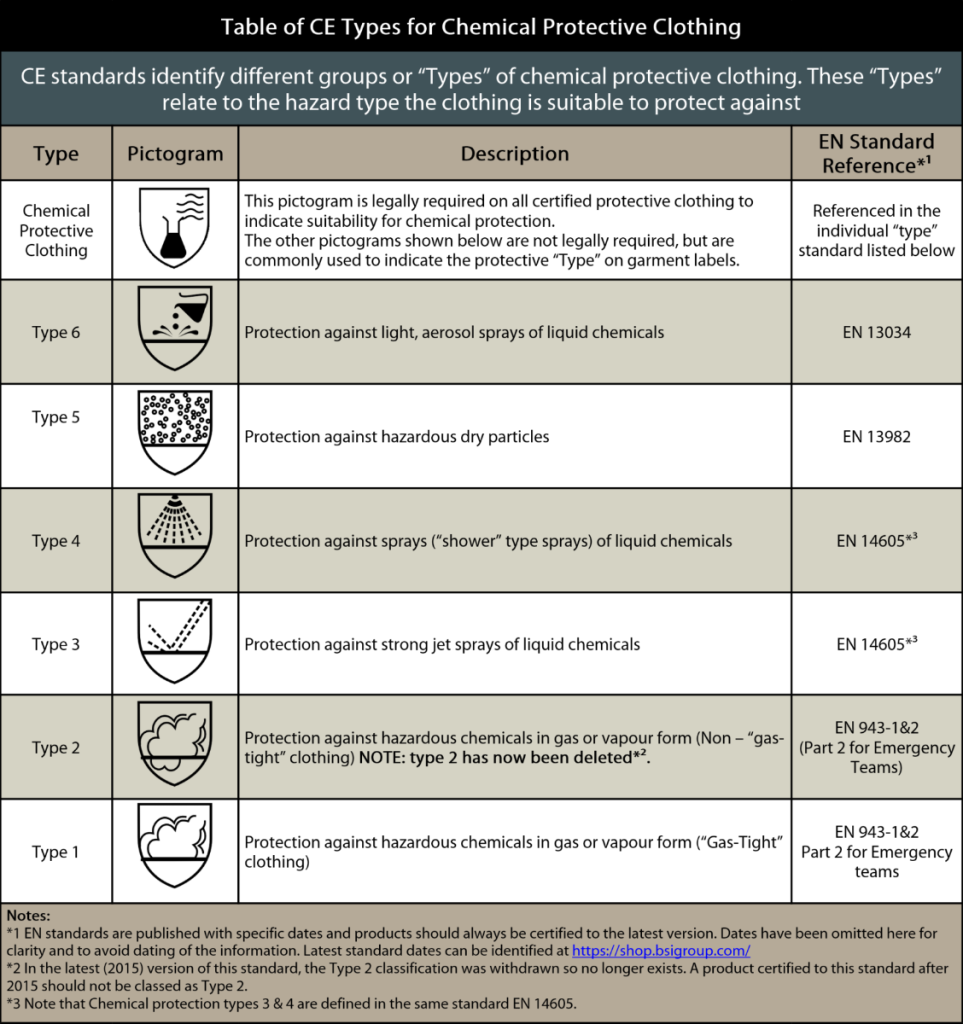

If you have researched into your coverall requirements, you may have noticed different types of suit including type 3, 4, 5 or 6. To ensure you provide the correct PPE for your employees you need to understand what these types mean.

The coverall type is determined by the tests it undergoes. The tests and results are quite complex to ensure the wearers ultimate safety. As a guide the 4 types are tested for the following penetrations:

Type 3 – Strong jet sprays of liquids are targeted at weak points within the suit to ensure protection

Type 4 – Shower spray from any angle, rotating over 1 minute.

Type 5 – Dust exposure

Type 6 – Exposure to a light aerosol spray

Having the right suit type isn’t enough without having an understanding of the tests it has undergone, the substances you are working with and the environment in which its being used.

The table shows the types of CE Certified suits available, the description and level of protection they can offer and the EN Standards that they conform with.

If you are unsure which type of coverall you need please contact our team, who can help you. It is so important you get the right coverall for your processes to keep your employees safe and fully protected.

Be sure your coveralls are tried and tested

Be sure your coveralls are tried and tested

In a world where everything can be purchased cheaper, a person’s health should never be compromised. Coveralls need not be expensive, but they do need to be effective and fit for purpose, so please ensure you check with your supplier what tests the coveralls have undergone. All PPE should go through rigorous and independent assessment and all certification for your coveralls should be made available, and a copy should be kept on your records.

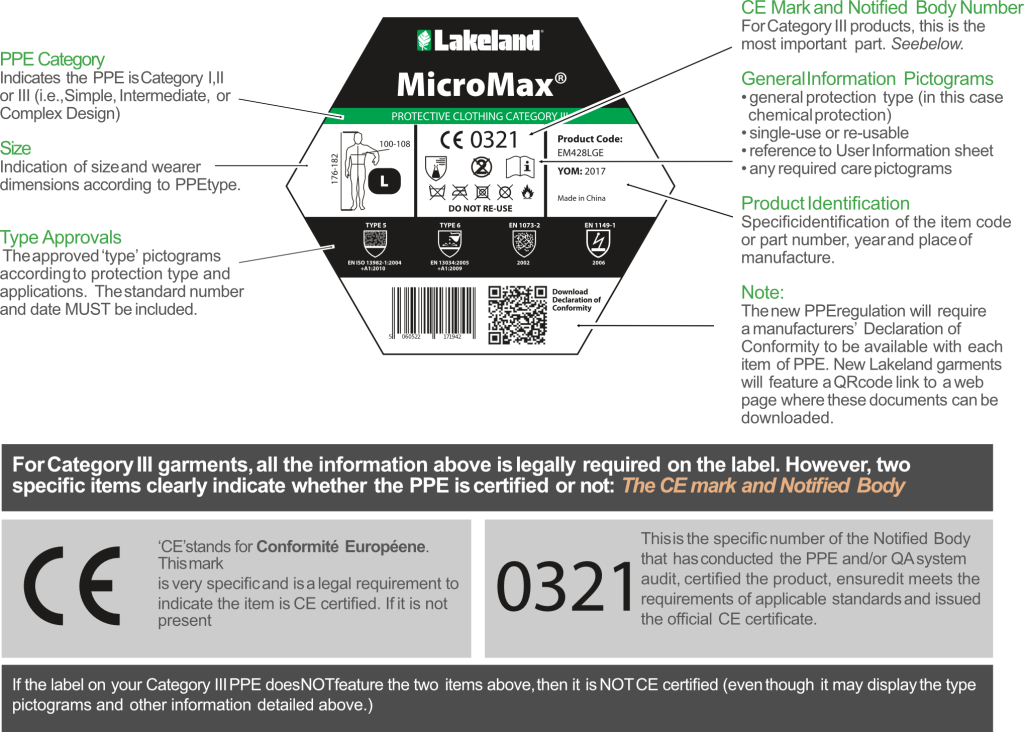

How do you know if PPE is certified correctly? By law PPE must be CE certified if it is to be sold in Europe. PPE is usually certified to a relevant EN product performance standard. All EN certified products should feature a label with very specific information relevant to the type of PPE which is a legal requirement. Lakeland CE Certification leaflet provides full details

The certification label for coveralls should include the following information as a minimum:

· PPE Category

· Size

· Type approvals

· CE Mark and Notified Body Number

· Pictograms

· Product Identification

· Manufacturers Declaration of Conformity

All of the above information is legally required for Category III PPE. Two specific items clearly indicate whether the PPE is certified or not, these are the CE Mark and Notified Body Number.

If in doubt please ask your supplier to provide evidence your PPE is CE Certified.

We appreciate Health and Safety officers have a lot of responsibilities in the workplace and time is often limited. We hope you found our guide to coveralls useful, please feel free to share it with anyone you think would benefit.

Spillcraft are here to help, whether you are looking for advice on PPE you provide, the spill control required on your site, training, or a managed replenishment service, we are available to help take some of the pressure away.

Call: 01606 352 679 | Email: [email protected]

Spill Training | Site Surveys | Managed Spill Services | Spill Equipment